[From the last episode: PhotolithographyA way of creating patterns on a silicon wafer for selective deposition or etching. You can think of it as taking a picture of the pattern and having it show up on the wafer. In the industry, photolithography is often abbreviated as lithography. allows us to be selective about where we add material and where we remove it.]

Before we dive into how sensorsA device that can measure something about its environment. Examples are movement, light, color, moisture, pressure, and many more. and actuatorsA way of controlling some device electronically. It might turn the device on or off or change a setting or property or do any other thing that the device is capable of. are made, here’s an important question: Sensors aren’t new, so why all the hullabaloo now?

Old and Bulky Don’t Cut It

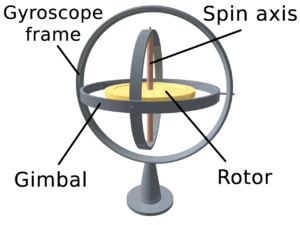

OK, nothing wrong with old, but bulky sensors limit what we can do. Sensors have been around for a long, long time. GyroscopesA sensor that detects when it changes direction. for navigation aren’t new. The sensors for firing your car’s airbags used to be tubes with balls in them. And, of course, we’ve had thermometersA sensor that measures temperature. forever, it seems. Same with lots of other sensors and actuators.

Here’s the problem: the venerable old versions are big. Oh, and, often, expensive. But still: your phone probably has a gyroscope in it. D o you think that would be possible with the version shown on the right?

o you think that would be possible with the version shown on the right?

Not likely.

So what’s changed? The scale has changed. (And the cost too, but you can still pay a lot of money for a super-accurate gyroscope…) So let’s take a minute to talk about scale.

Taking a Cue from Metric Units

How do we even talk about scale? After all, what’s big to a toddler might be small to an adult. It’s relative. So we need some frame of reference. When we talk about computing, for example, we talk in terms of the number of operations we can complete in one second. When talking semiconductorA material that, under some circumstances, can conduct electricity and, in other circumstances, cannot. chipsAn electronic device made on a piece of silicon. These days, it could also involve a mechanical chip, but, to the outside world, everything looks electronic. The chip is usually in some kind of package; that package might contain multiple chips. "Integrated circuit," and "IC" mean the same thing, but refer only to electronic chips, not mechanical chips., we talk in terms of how big different features are – as a fraction of a meter.

We do this using the same prefixes as we use for the metric system (with apologies to anyone for whom this is review). If you look at the table on that linked Wikipedia page, you’ll notice that most of the prefixes reflect sizes that are 1000 times bigger or smaller than the next size (there are a few exceptions). (And, for those 1000x prefixes, the ones bigger than 1 are all capitalized – except for kilo – and the ones smaller than 1 are all lower case.)

So when computer scientists talk about future computers that can handle 1018 operations per second, they talk about “exascale” computing, since “exa” is the prefix for 1018. For sensors and actuators, however, what we care about is the scale of mechanical features. The old “default” versions we generically refer to as “macro-scale” – “macro” meaning “big” (but in an unspecific way).

But there are two levels of scale that we talk about with leading-edge sensors. The most common is “microscale”: devices with features measured in microns, or micrometers – a thousandth of a meter. We talked a little about this in an earlier post. And most new miniaturized sensors have features in this range.

Beyond Micro

But the next goal – one that has been achieved in research – is “nanoscale.” “Nano” is the next smaller prefix after “micro,” so it’s easy to think of nanoscale as a bit smaller than microscale. But it’s not just a bit smaller; it’s a thousand times smaller. It’s so small that there’s really not much that we can use from our macro-scale world as a comparison. Using the overused human hair metric (which we saw as 17 to 181 μm in thickness before), then a nanometer is about one seventeen-thousandth of a thin hair and one one-hundred-eighty-one-thousandth of a thick hair.

Yeah, kind of hard to visualize.

But bear in mind that we measure older sensors and actuators in inches (or centimeters). If centimeters are a hundredth of a meter, then microscale is 10,000 times smaller; nanoscale is 10,000,000 times smaller. Mind-boggling.

This makes it possible to create small, cheap sensors that fit, for example, in your phone. Now… because cheap sensors are now possible, the cheapest ones won’t be as accurate or stable as the old-school ones. But you can still make accurate small sensors – it’s just that they cost more (and you probably wouldn’t want to pay for them in your phone).

One other point of comparison: electronic circuits on chips have nanoscale features. Most sensors have microscale features. So, to someone who is used to working with circuits, sensors seem huge – a thousand times bigger. But for us everyday folks, they’re all miniscule. That’s why we’re using siliconAn element (number 14 in the periodic table) that can be a semiconductor, making it the material of preference for circuits and micro-mechanical devices. circuit techniques to build the mechanical devices: even though they’re much bigger than today’s circuits, circuits back in the 70s and 80s were about this size. And we used many of the same manufacturing techniques back then.

Boggles the Mind…

So it can be hard to wrap your head around the sizes we’re talking about, but it’s good to keep in mind just how small this stuff is. You’ll see some crazy techniques that we use to build them, and that’s because we can’t do old-school machining at this scale. Whether micro or nano, it’s all just ridiculously small.

Leave a Reply