[From the last episode: A full sensorA device that can measure something about its environment. Examples are movement, light, color, moisture, pressure, and many more. contains the basic transducerA device that converts one kind of energy, like the energy of motion, into another, like the energy of an electric current. Transducers are fundamental to sensors, since they let us measure something physical as an electric current. plus circuitry to clean things up and, usually, convert to digital.]

Here we take a look at our first real sensor: the accelerometer. Like the name suggests, it measures acceleration. This was actually the first sensor application to be driven hard into high volumes because it could be used trigger airbags in cars.

As this is the first sensor we’re looking into, we’re going to break it down a bit more than we will the other ones. In order to understand how this works, we need to answer three questions:

- What physical phenomenon can we use?

- What physical shapes can we use to measure this?

- How will we turn the physical phenomenon into an electrical measurement?

Acceleration Breakdown

Let’s start with the first question. With an accelerometer, that phenomenon is inertiaThe tendency for an object to keep moving (or not moving) at a constant speed if you don’t accelerate or decelerate it. There’s inertia in a straight line and there’s also inertia of rotation – spinning things want to keep rotating in a specific direction unless you force them to change.. It’s best expressed as Newton’s First Law, as noted in Wikipedia: “… an object either remains at rest or continues to move at a constant velocity, unless acted upon by a force.” Perhaps another way of saying this is, “Everything stays the same unless you change it.” For motion, that change is acceleration (which includes deceleration — negative acceleration).

That law refers to straight-line motion, but it also holds for rotation. With accelerometersA sensor that measures acceleration and deceleration., we’re dealing with straight lines; gyroscopesA sensor that detects when it changes direction. (which we’ll look at after accelerometers) deal with things that spin.

You, of course, experience the First Law all the time. When your car accelerates, you feel the pushback into your seat; when you decelerate, you tend to lean forward. If you decelerate too quickly, you run the risk of having your head go through the windshield. Seatbelts have protected us for a long time, but modern airbags use this very fact to deploy if you decelerate too quickly.

Because of these familiar experiences, it probably feels natural that you can “feel” or measure acceleration most easily if you have some large something that wants to keep moving (or not moving). The heavier the thing, the more it’s going to push back or forwards. This is exactly the concept that MEMS accelerometers rely on, although by comparison to our macro world, that “chunk” of matter is really small. They call the chunk the proof mass.

The smaller the proof mass is, the harder it is to measure accurately. So there’s this balancing act that sensor designers need: as big a proof mass as possible, but small enough to fit into the tiny spaces of a MEMS chipAn electronic device made on a piece of silicon. These days, it could also involve a mechanical chip, but, to the outside world, everything looks electronic. The chip is usually in some kind of package; that package might contain multiple chips. "Integrated circuit," and "IC" mean the same thing, but refer only to electronic chips, not mechanical chips..

Diving In

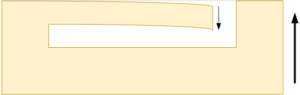

So… on to the second question: what shapes might we use here? The simplest one is what is technically called a cantilever, but it’s more familiar as a diving board. The idea is that, just like a real diving board, the platform is a little springy. If you move it up, the end of the board wants to stay where it was, and the whole thing bends down. Or, if you move it down, then the board bends up.

We can use this drawing to illustrate the concept, although there are many different ways to do it. The first drawing shows the basic cantilever at restA way of programming that has evolved out of web programming, and it’s more abstract than other older languages like C.. Note that this may be made out of many different substances, but siliconAn element (number 14 in the periodic table) that can be a semiconductor, making it the material of preference for circuits and micro-mechanical devices. is a common one. So this could be inside the waferIn the context of making circuits, sensors, and actuators, a thin, round slice of pure silicon. Multiple devices will be made on it; it will then be sliced up to separate the individual chips. if bulk micromachined, or it could be built on top of the wafer if surface micromachined.

If we move the entire thing up, then the end of the cantilever, which wants to stay where it was, looks like it moves down.

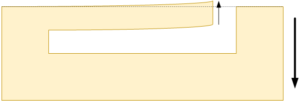

Or the reverse: if we move the entire thing down, then the cantilever end wants to move up.

But… but… but…

Now… if you know that silicon is a crystal, then you know that it’s really rigid and brittle. So you could reasonably ask, how can silicon bend up or down like that? Wouldn’t it be too hard to bend? And if it bent, wouldn’t it just break??

And the answers are surprising: no and no. Even though it is a hard crystal, there is some give. There’s a small range within which that platform can wiggle. And, if you don’t wiggle it too far, the movement is elastic: you push a little and it moves a little; you push twice as hard and it moves twice as much. That, plus way more complicated math, lets you decide how much movement means how much acceleration.

The other big question would be, if we vibrate this thing too long, will it eventually break? That’s what we call fatigue – the material “gets tired” and gives up. It’s a super important thing in, for example, airplanes. More than one plane has gone down because some part of it suffered from fatigue; it wore out.

This is something that MEMS designers don’t take for granted. If they keep the motion reasonable – if they don’t rattle the end of the cantilever too far – then the thing pretty much keeps going. But they test it – they run these things for billions of cycles to prove what they believe.

G Force

One other important note: We show the “at rest” version first up there. But such a version doesn’t exist on earth; it can’t. The reason is one word: gravity. We experience gravity as an acceleration, so a cantilever that looks like it’s at rest, if it’s sitting like the one shown, will bend slightly down because gravity pulls it down. That may sound obvious or even trivial, but, as we’ll see later, we have to take gravity into account for a number of different things.

Next we need to consider two questions:

- This accelerometer gives us the acceleration in one direction. How do we measure it in any direction?

- We may be able to calculate how much that cantilever will move with a certain amount of acceleration, but how do we turn that into an electrical signal that we can communicate to the rest of the systemThis is a very generic term for any collection of components that, all together, can do something. Systems can be built from subsystems. Examples are your cell phone; your computer; the radio in your car; anything that seems like a "whole." (whatever the system is)?

Our next two posts will answer those questions.

Leave a Reply